Paver Block / Interlocking paver Block

An interlocking paving ( Paver Blocks, Paver Brick, concrete Block, concrete tiles ) stone market is a piece of precast concrete or brick, often outdoor hardscaping applications. Developed in Europe and the United States in the early 1970s.

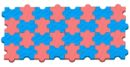

Interlocking pavers on a compacted stone base and a leveling bed of sand are installed, concrete pavers for driveways, patios, pool decks and walkways and docks to the airport or used loading.

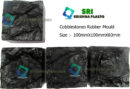

Fast Moving Interlocking Paver Moulds

Instead of the Pavers ( Paver Blocks, Paver Brick, concrete Block, concrete tiles) by pouring grout between the joints as with tiles, sand grains are spread over the pavement and compacted. The sand stabilizes the interlocking Pavers ( Paver Blocks, Paver Brick, concrete Block, concrete tiles), yet allows some flexibility. This type of paving absorb stress such as small earthquakes, freezing and thawing, soil erosion and slight shift each tile slightly. Therefore, they will not crack or buckle like concrete, but bad weather can make potholes.

Paving bricks are laid on a bed of sand, southwest England

special tool required for installation interlocking pavers ( Paver Blocks, Paver Brick, concrete Block, concrete tiles) vibrating machine, or compaction “Vibra Plate cutter and scissors. The first is the compact the base material to a minimum density of 90% used and also to define and block pavers ( Paver Blocks, Paver Brick, concrete Block, concrete tiles) in the sand bed. The latter is used for cutting the pieces fit into the corners and edges. The sand is not too easy, can stimulate or water hose and a sealant over the sand wash block distributed.

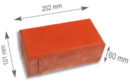

Standard thicknesses are 60mm Paver Blocks ( Interlocking paver Block, Paver Brick, concrete Block, concrete tiles) (for light vehicles) and 80mm (high) Paver Blocks ( Interlocking paver Block, Paver Brick, concrete Block, concrete tiles). 50mm Paver Blocks ( Interlocking paver Block, Paver Brick, concrete Block, concrete tiles) is all too common in some countries such as India,Bangladesh , Pakistan (for sidewalks, etc.).

Manufacturing of Paver Blocks ( Interlocking paver Block, Paver Brick, concrete Block, concrete tiles)

Composite stones are made by machines in factories. They consist of two fine aggregates and coarse grains, with compounds of cement. The ingredients are the ongoing pressure and vibration, producing undergoing a strong, durable concrete, which can then be formed into various shapes and designs.

Manufacture of paving stones is made on two types of machines in general. The former is more popular, cost more productive, more efficient and products of high strength blocks machines. The movements are controlled hydraulically and compaction is eccentric weight vibrators. The other option is, hydraulic presses, which will benefit each deny the above still in some countries due to their low demand for capital common. There is no vibration to move the material into the mold can therefore now be empty. For the former world leader Germany, Masa and Hess. Machines such as the British and Americans are strong competitors better. Some Chinese companies on the market, but they usually follow or copy the design of this guide.

The benefits of paving asphalt and concrete poured, high compressive strength (7000 psi BS + 8000 + psi and in the codes and ASTM), nice views, saves time, easy removal and relays, etc.

Products Category

- 3d epoxy flooring

- Anti Corrosive Paint

- Chemicals

- Coating

- Colors and Pigments

- Concrete Garden Bench Mould

- Cover Block rubber Mould

- Cube Mould

- Drain Cover Moulds

- Grass Paver Mould

- Hydraulic Press Tile Press Paver Block Making Machine

- Interlocking Paver Moulds

- iron Oxide

- Machines

- Precast Compound Wall moulds

- precast boundary wall molds

- precast compound wall mould

- precast Manhole Cover Moulds

- Precast Tree Guard Mould

- Railway platform chair bench mould

- ready mix truck cleaner chemical

- waterproofing admixture